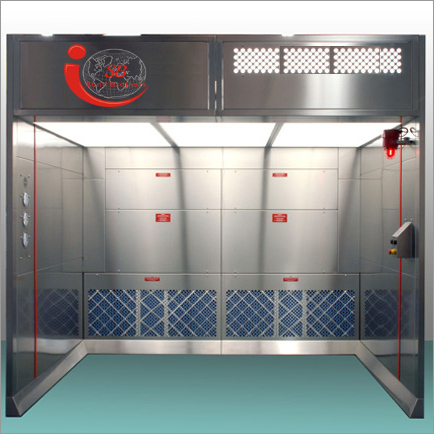

Inoculation Chamber

Inoculation Chamber Specification

- Control Type

- Manual Switch

- Display Type

- No Display

- Glass Type

- Acrylic Transparent sheet (front panel)

- Power Supply

- Single Phase AC

- Features

- UV light for sterilization, Ergonomic design, Portable, Light weight, Easy to clean

- Heating Capacity

- No Heating (Standard)

- Shape

- Rectangular

- Temperature Resistance

- Up to 60C

- Type

- Inoculation Chamber

- Dimension (L*W*H)

- 610 x 610 x 900 mm

- Equipment Type

- Biological Safety Cabinet

- Equipment Materials

- Mild Steel with Powder Coating

- Power

- 220V / 50Hz

- Voltage

- 220 Volt

- Material

- Stainless Steel & Transparent Acrylic Sheets

- Application

- Microbiological laboratory and sterile operations

- Capacity (Ltr)

- Customizable based on model

Inoculation Chamber Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AMBALA

- Supply Ability

- 5000 Pieces Per Year

- Delivery Time

- 1 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Eastern Europe, Central America, Middle East, South America, Western Europe, Australia, Asia, North America, Africa

- Main Domestic Market

- All India

About Inoculation Chamber

- The clients can avail highly functional Inoculation Chambers.

- This Economical Inoculation Chamber clean-air chamber .

- generally used for transfer of tissues and other tissues culture work.

- also as a dry-box and by dust proof bacteria free clean uncontaminated environmental enclosure.

- specifically Our Inoculation Chambers fabricated out of thick ply board clad,

- externally laminated sheet and inner exposed areas painted with chemically resistant Epoxy paint.

- This Inoculation Chambers is provided with tightly covered rectangular opening on one side for putting in the material.

- A clear fixed acrylic sheet window provided in front for observation. Complete with fluorescent lighting and germicidal ultra violet tube

Ergonomic and Adaptable Design

This inoculation chamber is developed with user comfort and adaptability in mind. The transparent acrylic panels and accessible folding/sliding door provide clear visibility and effortless sample handling. Its rectangular shape and durable materials make it suitable for diverse sterile work requirements.

UV Germicidal Sterilization

The integrated UV sterilization lamp effectively reduces microbial contamination between uses. Combined with a fluorescent lamp for optimal visibility, this chamber ensures an uncompromised sterile workspace without the need for air flow or heating elements.

Portability and Versatility

With its lightweight build and rubber stoppers, the chamber is portable and stable on any laboratory table. Customizable capacity and equipment material options (stainless steel or mild steel) address specific operational needs while maintaining safety standards.

FAQs of Inoculation Chamber:

Q: How does the inoculation chamber provide a sterile environment?

A: The chamber uses a UV germicidal lamp for thorough sterilization between usage, combined with still air design to limit contamination. Its construction with powder-coated mild steel and transparent acrylic panels further reduces contamination risks.Q: What are the standard dimensions and material options for this inoculation chamber?

A: The standard dimensions are 610 x 610 x 900 mm, and it is constructed from mild steel with powder coating and transparent acrylic sheets. The work surface can be customized to stainless steel or mild steel based on laboratory requirements.Q: When should the UV germicidal lamp be used during laboratory procedures?

A: The UV sterilization lamp should be activated before and after handling samples to eliminate potential contaminants and ensure aseptic working conditions for each procedure.Q: Where is this chamber typically utilized?

A: It is primarily used in microbiological laboratories and environments that require sterile operations, such as research institutions, pharmaceutical industries, and clinical diagnostics labs.Q: What is the process for cleaning and maintaining the inoculation chamber?

A: The chambers surfaces are designed for easy cleaning using standard laboratory disinfectants. Clear the chamber of instruments, wipe down all surfaces, and regularly operate the UV lamp according to safety protocols.Q: What are the main benefits of using this inoculation chamber over alternatives?

A: Key advantages include effective UV-based sterilization, ergonomic and portable design, low operational noise (below 65 dB), and the flexibility of customizable sizing and work surfaces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Equipment Category

Chromatography Cabinet

Price 8500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : 0.5 kW

Application : For separation and purification in research laboratories

Material : Stainless Steel / Mild Steel

Incubators Bacteriological

Price 10500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 220V AC

Application : Bacteriological Incubation

Material : Stainless Steel

Sampling Dispensing Booth

Price Range 100000.00 - 150000.00 INR

Minimum Order Quantity : 1 , , Unit

Power : Standard

Application : Sampling and Dispensing Operations in Laboratories and Industrial Settings

Material : Stainless Steel & Glass

Fume Hood

Price 150000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : 2 Horsepower (HP)

Application : Industrial

Material : Aluminium Alloy

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS